Our Products: Geotech Tooling

Rotary Tools

| DCDMA Casing Type |

Outside Diameter | Inside Diameter | Threads Per Inch |

Assembly Length | Assembly Part Number |

|---|---|---|---|---|---|

| AW | 2-1/4-inch (57mm) | 1-29/32-inch (48.4mm) | 4-TPI | 2-Foot (610mm) | AWC-RH-02 |

| AW | 2-1/4-inch (57mm) | 1-29/32-inch (48.4mm) | 4-TPI | 3-Foot (914.4mm) | AWC-RH-03 |

| AW | 2-1/4-inch (57mm) | 1-29/32-inch (48.4mm) | 4-TPI | 5-Foot (1.5m) | AWC-RH-05 |

| AW | 2-1/4-inch (57mm) | 1-29/32-inch (48.4mm) | 4-TPI | 10-Foot (3m) | AWC-RH-10 |

| BW | 2-7/8-inch (73mm) | 2-3/8-inch (60.3mm) | 4-TPI | 2-Foot (610mm) | BWC-RH-02 |

| BW | 2-7/8-inch (73mm) | 2-3/8-inch (60.3mm) | 4-TPI | 3-Foot (914.4mm) | BWC-RH-03 |

| BW | 2-7/8-inch (73mm) | 2-3/8-inch (60.3mm) | 4-TPI | 5-Foot (1.5m) | BWC-RH-05 |

| BW | 2-7/8-inch (73mm) | 2-3/8-inch (60.3mm) | 4-TPI | 10-Foot (3m) | BWC-RH-10 |

| NW | 3-1/2-inch (89mm) | 3-inch (76.2mm) | 4-TPI | 2-Foot (610mm) | NWC-RH-02 |

| NW | 3-1/2-inch (89mm) | 3-inch (76.2mm) | 4-TPI | 3-Foot (914.4mm) | NWC-RH-03 |

| NW | 3-1/2-inch (89mm) | 3-inch (76.2mm) | 4-TPI | 5-Foot (1.5m) | NWC-RH-05 |

| NW | 3-1/2-inch (89mm) | 3-inch (76.2mm) | 4-TPI | 10-Foot (3m) | NWC-RH-10 |

| HW | 4-1/2-inch (114.3mm) | 4-inch (101.6mm) | 4-TPI | 2-Foot (610mm) | HWC-RH-02 |

| HW | 4-1/2-inch (114.3mm) | 4-inch (101.6mm) | 4-TPI | 3-Foot (914.4mm) | HWC-RH-03 |

| HW | 4-1/2-inch (114.3mm) | 4-inch (101.6mm) | 4-TPI | 5-Foot (1.5m) | HWC-RH-05 |

| HW | 4-1/2-inch (114.3mm) | 4-inch (101.6mm) | 4-TPI | 10-Foot (3m) | HWC-RH-10 |

| PW | 5-1/2-inch (139.7mm) | 5-inch (127mm) | 3-TPI | 2-Foot (610mm) | PWC-RH-02 |

| PW | 5-1/2-inch (139.7mm) | 5-inch (127mm) | 3-TPI | 3-Foot (914.4mm) | PWC-RH-03 |

| PW | 5-1/2-inch (139.7mm) | 5-inch (127mm) | 3-TPI | 5-Foot (1.5m) | PWC-RH-05 |

| PW | 5-1/2-inch (139.7mm) | 5-inch (127mm) | 3-TPI | 10-Foot (3m) | PWC-RH-10 |

| SW | 6-5/8-inch (168mm) | 6-inch (152.4mm) | 3-TPI | 2-Foot (610mm) | SWC-RH-02 |

| SW | 6-5/8-inch (168mm) | 6-inch (152.4mm) | 3-TPI | 3-Foot (914.4mm) | SWC-RH-03 |

| SW | 6-5/8-inch (168mm) | 6-inch (152.4mm) | 3-TPI | 5-Foot (1.5m) | SWC-RH-05 |

| SW | 6-5/8-inch (168mm) | 6-inch (152.4mm) | 3-TPI | 10-Foot (3m) | SWC-RH-10 |

| DCDMA Casing Type | Wireline Type Casing Advancer |

Assembly Part Number |

|---|---|---|

| BW | Yes | 59090 |

| NW | Yes | 59000 |

| DCDMA Casing Type | Casing Shoe Cutting Surface | Threads Per Inch | Assembly Part Number |

|---|---|---|---|

| AW | Standard Heat Treated | 4-TPI | AW-RH-DS |

| AW | Diamond Impregnated | 4-TPI | AWC-DS-RH-DI |

| AW | Chunky-Carbide “Devils Nightmare” | 4-TPI | AWC-DS-RH-DN |

| BW | Standard Heat Treated | 4-TPI | BWC-RH-DS |

| BW | Diamond Impregnated | 4-TPI | BWC-DS-RH-DN |

| BW | Chunky-Carbide “Devils Nightmare” | 4-TPI | BWC-DS-RH-DN |

| NW | Standard Heat Treated | 4-TPI | NWC-DS-RH |

| NW | Diamond Impregnated | 4-TPI | NWC-DS-RH-DI |

| NW | Chunky-Carbide “Devils Nightmare” | 4-TPI | NWC-DS-RH-DN |

| HW | Standard Heat Treated | 4-TPI | HWC-DS-RH |

| HW | Diamond Impregnated | 4-TPI | HWC-DS-RH-DI |

| HW | Chunky-Carbide “Devils Nightmare” | 4-TPI | HWC-DS-RH-DN |

| PW | Standard Heat Treated | 3-TPI | PWC-DS-RH |

| PW | Diamond Impregnated | 3-TPI | PWC-DS-RH-DI |

| PW | Chunky-Carbide “Devils Nightmare” | 3-TPI | PWC-DS-RH-DN |

| SW | Standard Heat Treated | 3-TPI | SWC-DS-RH |

| SW | Diamond Impregnated | 3-TPI | SWC-DS-RH-DI |

| SW | Chunky-Carbide “Devils Nightmare” | 3-TPI | SWC-DS-RH-DN |

| DCDMA Casing Type |

Outside Diameter | Inside Diameter | Threads Per Inch |

Assembly Length | Assembly Part Number |

|---|---|---|---|---|---|

| HWT | 4-1/2-inch (114.3mm) | 4-inch (101.6mm) | 2-1/2-TPI | 2-Foot (610mm) | HWT-RH-02 |

| HWT | 4-1/2-inch (114.3mm) | 4-inch (101.6mm) | 2-1/2-TPI | 5-Foot (1.5m) | HWT-RH-05 |

| HWT | 4-1/2-inch (114.3mm) | 4-inch (101.6mm) | 2-1/2-TPI | 10-Foot (3m) | HWT-RH-10 |

| PWT | 5-1/2-inch (139.7mm) | 5-inch (127mm) | 2-1/2-TPI | 2-Foot (610mm) | PWT-RH-02 |

| PWT | 5-1/2-inch (139.7mm) | 5-inch (127mm) | 2-1/2-TPI | 5-Foot (1.5m) | PWT-RH-05 |

| PWT | 5-1/2-inch (139.7mm) | 5-inch (127mm) | 2-1/2-TPI | 10-Foot (3m) | PWT-RH-10 |

| T-Series Casing Type | Wireline Type Casing Advancer |

Assembly Part Number |

|---|---|---|

| HWT | Yes | 3000863 |

| PWT | Yes | 3543991 |

| DCDMA Casing Type | Casing Shoe Cutting Surface |

Threads Per Inch | Assembly Part Number |

|---|---|---|---|

| HWT | Standard Heat Treated | 2-1/2-TPI | HWT-DS-RH |

| HWT | Diamond Impregnated | 2-1/2-TPI | HWT-DS-RH-DI |

| HWT | Chunky-Carbide “Devils Nightmare” | 2-1/2-TPI | HWT-DS-RH-DN |

| PWT | Standard Heat Treated | 2-1/2-TPI | PWT-DS-RH |

| PWT | Diamond Impregnated | 2-1/2-TPI | PWT-DS-RH-DI |

| PWT | Chunky-Carbide “Devils Nightmare” | 2-1/2-TPI | PWT-DS-RH-DN |

| Description | Moyno 2L4 | Moyno 2L6 | Moyno 3L4 | Moyno 3L6 | Moyno 3L8 |

|---|---|---|---|---|---|

| Rotor | 32006 | 32030 | 32054 | 32078 | 32102 |

| Rotor Band | 32017 | 32041 | 32065 | 32089 | 32113 |

| Stator | 32005 | 32029 | 32053 | 32077 | 32101 |

| Stator Support | 32013 | 32037 | 32061 | 32085 | 32109 |

| Connecting Rod Kit with Rod, Rotor & Main Drive Shaft Pin, Washers, Screws & Rotor Band | 32024 | 32048 | 32072 | 32096 | 32120 |

| Suction Housing (Body) | 32002 | 32026 | 32050 | 32073 | 32098 |

| Suction Body (Pump) Support | 32012 | 32036 | 32060 | 32084 | 32108 |

| Reducer | 32004 | 32028 | 32052 | 32076 | 32100 |

| Main Drive Shaft | 32007 | 32031 | 32055 | 32079 | 32103 |

| Main Drive Shaft Collar | 32016 | 32040 | 32064 | 32088 | 32112 |

| Main Drive Shaft Collar Pin Retainer | 32134 | 32135 | 32136 | 32137 | 32132 |

| Bearing - Radial | 32008 | 32032 | 32056 | 32080 | 32104 |

| Seal – Radial, Grease Type | 32021 | 32045 | 32069 | 32093 | 32117 |

| Bearing - Thrust | 32009 | 32033 | 32057 | 32081 | 32105 |

| Seal – Thrust, Grease Type | 32022 | 32046 | 32070 | 32094 | 32118 |

| Bearing Housing | 32003 | 32027 | 32051 | 32075 | 32099 |

| Bearing Spacer | 32010 | 32034 | 32058 | 32082 | 32106 |

| Bearing Cover Plate | 32011 | 32035 | 32059 | 32083 | 32107 |

| Bearing Lock Nut | 32019 | 32043 | 32066 | 32091 | 32115 |

| Bearing Lock Nut Washer | 32020 | 32044 | 32068 | 32092 | 32116 |

| Packing Gland | 32014 | 32038 | 32062 | 32086 | 32110 |

| Packing Gland Insert | 32023 | 32047 | 32071 | 32095 | 32119 |

| Packing Kit | 32015 | 32039 | 32063 | 32087 | 32111 |

| Lantern Ring | 32018 | 32042 | 32066 | 32090 | 32114 |

| Complete Pump Assembly | 32001 | 32025 | 32049 | 32074 | 32097 |

| Tri-Cone Bit Hole Size | Assembly Weight | Steel Tooth or Tungsten Carbide | Pin Up Connection | Assembly Part Number |

|---|---|---|---|---|

| 2-7/8-inch (73mm) | 3-Pounds (1.4 kg) | Steel Tooth | N-4 | 27106 |

| 2-15/16-inch (75mm) | 3-Pounds (1.4 kg) | Steel Tooth | N-4 | 27100 |

| 2-15/16-inch (75mm) | 3-Pounds (1.4 kg) | Tungsten Carbide | N-4 | 27100-TC-N4 |

| 3-1/4-inch (83mm) | 5-Pounds (2.3 kg) | Tungsten Carbide | N-4 | 27103-TC-N4 |

| 3-1/8-inch (79mm) | 4-Pounds (1.8 kg) | Steel Tooth | N-4 | 27102-ST-N4 |

| 3-7/8-inch (98.4mm) | 6-Pounds (2.7 kg) | Steel Tooth | 2-3/8” API Regular | 27113-ST-2375 |

| 3-7/8-inch (98.4mm) | 6-Pounds (2.7 kg) | Tungsten Carbide | 2-3/8” API Regular | 27113-TC-2375 |

| 4-inch (102mm) | 8-Pounds (3.6 kg) | Steel Tooth | 2-3/8” API Regular | 27105 |

| 4-1/2-inch (114.3mm) | 9-Pounds (4.1 kg) | Tungsten Carbide | 2-3/8” API Regular | 27117-TC-2375 |

| 5-1/8-inch (130mm) | 21-Pounds (9.5 kg) | Tungsten Carbide | 2-7/8” API Regular | 27116-TC-2875 |

| 5-5/8-inch (143mm) | 22-Pounds (10 kg) | Tungsten Carbide | 3-1/2” API Regular | 27118-TC-0350 |

| 5-7/8-inch (149.2mm) | 23-Pounds (10.4 kg) | Steel Tooth | 3-1/2” API Regular | 27119-ST-0350 |

| 5-7/8-inch (149.2mm) | 23-Pounds (10.4 kg) | Tungsten Carbide | 3-1/2” API Regular | 27119-TC-0350 |

| 6-inch (152mm) | 23-Pounds (10.4 kg) | Steel Tooth | 3-1/2” API Regular | 27114 |

| 7-7/8-inch (200mm) | Steel Tooth | 4-1/2” API Regular | 27112-ST-0450 | |

| 9-7/8-inch (251mm) | Steel Tooth | 6-5/8” API Regular | 27120-ST-6625 | |

| 12-1/4-inch (311mm) | Steel Tooth | 6-5/8” API Regular | 27121-ST-6625 |

| Chevron Style (Drag) Bit Hole Size | Assembly Weight | 3-Wing or 4-Wing |

Pin Up Connection | Assembly Part Number |

|---|---|---|---|---|

| 2-15/16-inch (75mm) | 4-Pounds (1.8 kg) | 3-Wing | N-4 | 27107 |

| 3-inch (76.2mm) | 4-Pounds (1.8 kg) | 3-Wing | NW | 27108 |

| 3-5/8-inch (92mm) | 6-Pounds (2.7 kg) | 3-Wing | N-4 | 27104 |

| 3-7/8-inch (98.4mm) | 6-Pounds (2.7 kg) | 3-Wing | 2-3/8” API Regular | 27117 |

| 4-1/2-inch (89mm) | 8-Pounds (3.6 kg) | 3-Wing | 2-3/8” API Regular | 27104 |

| 5-1/2-inch (140mm) | 17-Pounds (7.7 kg) | 3-Wing | 2-7/8” API Regular | 27118 |

| 6-inch (152mm) | 19-Pounds (8.6 kg) | 3-Wing | 3-1/2” API Regular | 27115 |

| Custom Built Stabilizer Length | Largest Outside Diameter | Top Connection | Bottom Connection | Special Feature | Assembly Part Number |

|---|---|---|---|---|---|

| 30-inch (762mm) | 9-7/8-inch (251mm) | 3-1/2” API Regular Pin | 6-5/8” API Regular Box | Smooth OD Bottle-Necked Wrench Flats On Box End | 27124 |

| 12-Foot (3.7 m) |

9-7/8-inch (251mm) | 2-7/8” API Regular Box | 6-5/8” API Regular Box | Wrench Flats On Both Ends | 27110 |

| DTH Style Bit Hole Size | Assembly Weight | Bit Face Design | Pin Up Connection | Assembly Part Number |

|---|---|---|---|---|

| 7-7/8-inch (200mm) | Concave Type | 360-Degree Shank | 27109 |

| Drill Pipe Outside Diameter | Assembly Length | Thread Type | Special Feature | Assembly Part Number |

|---|---|---|---|---|

| 2-7/8-inch (73mm) | 5-Foot (1.5m) | 2-3/8” Mayhew Junior Pin x 2-3/8” API Regular Box | Wrench Flats Box & Pin End | 27137 |

| 2-7/8-inch (73mm) | 10-Foot (3m) | 2-3/8” Mayhew Junior | Wrench Flats Box & Pin End | 27138 |

| 3-1/2-inch (89mm) | 1-Foot (305mm) | 2-3/8” API IF | No Wrench Flats | 27155 |

| 3-1/2-inch (89mm) | 2-Foot (610mm) | 2-3/8” API IF | No Wrench Flats | 27156 |

| 3-1/2-inch (89mm) | 10-Foot (3m) | 2-3/8” API IF | Wrench Flats Box & Pin End | 27157 |

| 3-1/2-inch (89mm) | 10-Foot (3m) | 2-3/8” API IF | Wrench Flats Box End | 27158 |

| 3-1/2-inch (89mm) | 20-Foot (6m) | 2-3/8” API IF | Wrench Flats Box & Pin End | 27159 |

| 3-1/2-inch (89mm) | 20-Foot (6m) | 2-3/8” API IF | Wrench Flats Box End | 27160 |

| 4-1/2-inch (114.3mm) | 20-Foot (6m) | 2-7/8” API IF | Wrench Flats Box End | 27131 |

| Sideport or Top Mount Swivel Assembly | Top Connection | Bottom Connection | Water Course (Inlet) Diameter | Assembly Weight | Assembly Part Number |

|---|---|---|---|---|---|

| Sideport | AW Box | AW Pin | ¾-inch (19mm) | 10-Pounds (4.5 kg) | 30009 |

| Sideport | 1-1/8-inch (29mm) Hex Shank |

AW Pin | 1-inch (25.4mm) | 10-Pounds (4.5 kg) | 30001 |

| Sideport | 1-1/8-inch (29mm) Hex Shank |

AWJ Pin | 1-inch (25.4mm) | 10-Pounds (4.5 kg) | 30002 |

| Sideport | 1-5/8-inch (41mm) | AW Pin | 1-inch (25.4mm) | 10-Pounds (4.5 kg) | 30005 |

| Sideport | 1-5/8-inch (41mm) | AWJ Pin | 1-inch (25.4mm) | 10-Pounds (4.5 kg) | 30010 |

| Sideport | 1-5/8-inch (41mm) | NW Pin | 1-inch (25.4mm) | 32-Pounds (14.5 kg) | 30003 |

| Sideport | 1-5/8-inch (41mm) | NWJ Pin | 1-inch (25.4mm) | 32-Pounds (14.5 kg) | 30004 |

| Sideport | 1-5/8-inch (41mm) | NWJ Pin | 2-inch (51mm) |

32-Pounds (14.5 kg) | 30007 |

| Sideport | 2-inch (51mm) | 2-3/8” Mayhew Junior Pin | 2-inch (51mm) |

45-Pounds (20.4 kg) | 30008 |

| Compact-Roto-Sonic Sideport | Bolt-Up Spindle Flange | Bolt-Up Spindle Flange | 1-inch (25.4mm) | 60-Pounds (27.2 kg) | 31-01-02 |

| Compact-Sonic Sideport | Uni-Thread Box with Spindle Clamp | Uni-Thread Pin | 1-inch (25.4mm) | 50-Pounds (23 kg) | 30-41-10 |

| Top Mount | Heavy Duty Bail | AWJ Pin | 1-1/4-inch (32mm) | 40-Pounds (18 kg) | 30051 |

| Top Mount | Heavy Duty Bail | NWJ Pin | 1-1/2-inch (38mm) | 50-Pounds (23 kg) | 30050 |

| Double-Rod Clamp Assembly Breaks Rod & Casing with OD |

Estimated Shipping Weight | Assembly Part Number |

|---|---|---|

| 2-1/2-inch (63.5mm) OD thru 7-5/8-inch (193.7mm) OD | 428-Pounds (194 kg) | 7100-500-27164 |

| 2-1/2-inch (63.5mm) OD thru 8-5/8-inch (219mm) OD | 428-Pounds (194 kg) | 7100-500-27165 |

| Jaw Inserts (8-Required) | Assembly Part Number |

|---|---|

| Compact-Sonic Head 2-1/2-inch (63.5mm) OD Thru 7-5/8-inch (193.7mm) OD | 500-27162 |

| Compact-Roto-Sonic 2-1/2-inch (63.5mm) OD thru 8-5/8-inch (219mm) OD | 500-27163 |

| K-Series Packer Outside Pipe Size | K-Series Packer Inside Casing Size | Coupling Type | Special Feature | Assembly Part Number |

|---|---|---|---|---|

| 2-inch (51mm) | NW-Casing 3-inch (76.2mm) |

Blank | For Schedule-40 PVC | 20207 |

| 2-inch (51mm) | HW-Casing 4-inch (102mm) |

Blank | For Schedule-40 PVC | 20208 |

| 2-inch (51mm) | HQ-Wireline 3-inch (76.2mm) |

Blank | For Schedule-80 PVC | 20205 |

| 2-inch (51mm) | HW-Casing 4-inch (102mm) |

Blank | For Schedule-80 PVC | 20206 |

Custom Built Mud Pits

Available from USExploration’s partner company Welltech Products they may be engineered/manufactured to your exact specifications.

Mud rotary drilling operations typically require the ability to re-circulate drilling fluids to conserve water use and help settle out cuttings for alternate disposal.

The ability to collar the bore hole at the surface assures that most, if not all of the return is captured above ground and can provide the drilling crew with extremely valuable down-hole data regarding the various formation types being encountered as part of the drilling process.

We also understand that the business end of every drill rig is not configured the same way, nor are drill sites identical – one from the other. Drillers also have specific preferences in how their mud pans are constructed including height, width, length, baffle configuration and over the road storage methods.

We have the in-house engineering and fabrication ability to complete your requirements on time and on budget while also accommodating your specific design requests.

Image 1

Lifting eyes (for use with drill rig hoist line) and handles can be arranged to your specification. (pictured: part number 27277 Mud Pit Assembly)

Image 2

Length, width, general configuration, and baffle placement are all to your specifications.

Image 3

The steel or aluminum plate is bent and shaped to minimize welded seams.

Image 4

Manufactured and shipped from Welltech’s facility in Pennsylvania assuring a timely turnaround for your order.

Image 5

4-Handles and 2-Lifting Eyes (shown) allow the crew to position the mud pit exactly where they need it on site.

Image 6

The seamless bottom assures the water & drilling mud stays where it is supposed to…in the pit or down-the-hole.

Image 7

The ability to collar the bore hole, not only inside the mud pit, but also underneath assures success in your mud rotary drilling application.

K-Series Packers – also referred to as Tri-Seals Available from USExploration Equipment Company and are designed to seal around Schedule-40 or Schedule-80 PVC.

Excellent for inhibiting flowing sands from migrating up or down the bore hole and typically made from neoprene rubber in two hardness ratings (Standard or Soft).

When ordering simply specify the Rods and Casing that you are working with and the general down-hole conditions.

K-Series Tri-Seal Packer

Hydraulic Double-Rod Clamp Assembly mounted to the base of our S-27CRS-T Roto-Sonic Track Rig can also be adapted to your existing mast or feedframe.

Each Jaw Insert is quickly replaced with 1-bolt & slides into a machined slot for proper orientation – every time!

(500-27163 pictured above)

Hydraulic Double-Rod-Clamp

Hydraulic Double-Rod Clamps

Manufactured by USExplorationEquipment Company and can be adapted to most multi-purpose or sonic & roto-sonic drilling rigs.

Typically mounted to the base of the mast/ feed frame, these exceptional tooling systems hold rods & casing with the bottom clamp and break the joint with the top (rotating) clamp.

This hands-free operation eliminates the need for pipe wrenches, cheater bars or hydraulic breakout wrenches.

The operator can simply pull the tool string up through the double-clamp with the head and then crib the down-hole tooling with the bottom clamp, while the top clamp rotates the (exposed) rods or casing until the joint can be spun off and racked for the next hole.

Each assembly includes a holding clamp, a breaking clamp & 8-jaw inserts.

Specify Drill Pipe, Casing or Drill Rod sizes when ordering

Compact Sonic Swivel

Top Mount Water Swivel

Sideport Water Swivel

Sideport & Top Mount Water Swivels

Available from USExploration Equipment Company.

Whether you are making a simple 5-foot (1.5m) “core run” at the bottom of the hole, doing air/ mud rotary, deep wireline coring or recovering a pavement core roadside, we have the correct Swivel for your application.

Typically the Sideport version is limited to smaller diameters and depths, because the water course is typically smaller, so flow is rather limited.

The Top Mounts can vary widely in terms of their water course, so installing them on top of the spindle and plumbing them to larger volume water/ mud pumps allows for greater flexibility in rotary or deep coring applications.

Drill Pipe with No Wrench Flats & API Tool Joints

Drill Pipe with Wrench Flats at Both Ends & API Tool Joints

Drill Pipe with API Tool Joints – Available from USExploration Equipment Company including API Regular, API Internal Flush (IF) and API Full-Hole.

Drill Pipes can be manufactured with wrench flats at one end or at both ends, depending on your preference and the breakout system on your existing machine.

When ordering simply specify the outside diameter, the desired thread type, and the shoulder-to-shoulder length that best fits your “top-head” or “table” drive drill rig.

Custom Built Stabilizers

Chevron Drag Bit

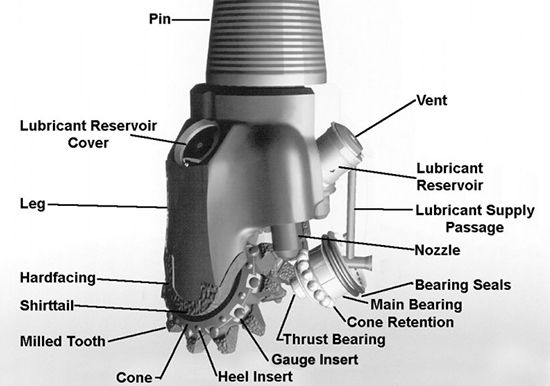

Tri-Cone Assembly Cut Away

Tri-Cone Bit

Tri-Cone & Chevron Style (Drag) Bits & Accessories – Available from USExploration Equipment Company.

Whether it is a 3-Wing or 4-Wing Drag (Chevron) Bit, Tri-Cone Roller Rock Bit, made-to-order Stabilizer or DTH Bit, we can deliver.

Complete L-Series Pumps available from stock

Replacement Parts for

your Moyno Pump

Moyno Pump & complete L-Series Assemblies parts – Available from USExploration Equipment Company to help keep that fluid circulating at the drill site.

Rotors, Stators, Packing Sets, Bushings, Bearings, Drive Shafts, Connecting Rod Kits, Mounting Frames and complete 2L-Series or 3L-Series Pumping Stations, either shipped loose or installed at our Indianapolis facility are just a phone call away.

When ordering repair parts simply specify the pump model (2L4, 2L6, 3L4, 3L6 and 3L8) and the appropriate subassembly. We'll handle the rest.

With Advancer locked into your Outer Driver Housing (short piece of casing) – the bore hole is closed off to the outside formation (Devil’s Nightmare Casing Shoe & Tri-Cone Bit shown) and assures that you can cut through both overburden & hard rock, while simultaneously advancing your casing and sealing off the (cased) bore hole from the surrounding lithology.

Looking up from the bottom of the bore hole, once the Advancer is removed from the casing, a clean (open) hole is exposed for soil sampling, rock coring, well placement or monitoring equipment installation (HWT x Devils Nightmare Casing Shoe shown).

The Outer Driver Housing easily threads onto the first piece of (5-foot or 10-foot long) flush joint casing, with the same threads, allowing you to simultaneously advance the hole & case off the formation.

The Driver Housing (short piece of lead casing) can be equipped with a wide variety of Casing Shoes, depending on the formation. Pictured above is an HWT x Devil’s Nightmare (Popcorn or Chunky Carbide) type. The Shoe cuts a slightly larger hole than the casing outside diameter, allowing the casing to follow this lead section smoothly down the bore hole.

The Wireline Casing Advancer locks into the Outer Driver Housing (short piece of casing) & sets/ retrieves the Advancer with the same Overshot assembly that you use for your wireline core barrel – when sampling intermittently or installing a well, packer or monitoring device.

HWT x Wireline Casing Advancer & 3-7/8” x Tungsten Carbide Bit (shown above). These lock into the HWT Outer Drive Housing (short piece of casing) at the bottom of your casing string, allowing you to convert your casing into a tool string and simultaneously advance and case the formation.

T-Series Flush Joint Casing & Accessories

Available from USExploration Equipment Company and comes in one style – multi-use type with heat treated tool joints.

This tapered, coarse threaded, flush joint casing has tremendous advantages over W-Design because it works vertically & really pays for itself at an angle.

It too is a very effective strategy for sealing off overburdened, weathered surface formations & large boulders when hollow stem augers are not an option.

Casing permits drilling fluids to circulate & return cuttings to the surface.

When ordering simply match your desired inside diameter with your required length to fit your down-hole application.

With Advancer locked into your Outer Driver Housing (short piece of casing) – the bore hole is closed off to the outside formation (Devil’s Nightmare Casing Shoe & Tri-Cone Bit shown) and assures that you can cut through both overburden & hard rock, while simultaneously advancing your casing and sealing off the (cased) bore hole from the surrounding lithology.

Looking up from the bottom of the bore hole, once the Advancer is removed from the casing, a clean (open) hole is exposed for soil sampling, rock coring, well placement or monitoring equipment installation (HWT x Devils Nightmare Casing Shoe shown).

The Outer Driver Housing easily threads onto the first piece of (5-foot or 10-foot long) flush joint casing, with the same threads, allowing you to simultaneously advance the hole & case off the formation.

The Driver Housing (short piece of lead casing) can be equipped with a wide variety of Casing Shoes, depending on the formation. Pictured above is an HWT x Devil’s Nightmare (Popcorn or Chunky Carbide) type. The Shoe cuts a slightly larger hole than the casing outside diameter, allowing the casing to follow this lead section smoothly down the bore hole.

The Wireline Casing Advancer locks into the Outer Driver Housing (short piece of casing) & sets/ retrieves the Advancer with the same Overshot assembly that you use for your wireline core barrel – when sampling intermittently or installing a well, packer or monitoring device.

HWT x Wireline Casing Advancer & 3-7/8” x Tungsten Carbide Bit (shown above). These lock into the HWT Outer Drive Housing (short piece of casing) at the bottom of your casing string, allowing you to convert your casing into a tool string and simultaneously advance and case the formation.

Flush Joint Steel Casing

DCDMA W-Design Flush Joint Casing and Accessories – Available from USExploration Equipment Company and come in two distinct styles: single use type with non-heat treated tool joints or multi-use type with heat treated tool joints.

Flush joint casing is part of any effective strategy for sealing off overburden, weathered surface formations and large boulders when hollow stem augers are not an option. Casing permits drilling fluids to circulate and return cuttings to the surface.

All sizes are specified by DCDMA Standards to allow nesting or telescoping and interchangeability between brands.

When ordering simply match your desired inside diameter with your required lengths & specify single use or multi-use to fit your down-hole application.

image 1

image 2

image 3

image 4

image 5

image 6

image 7